Description

Bullet Points

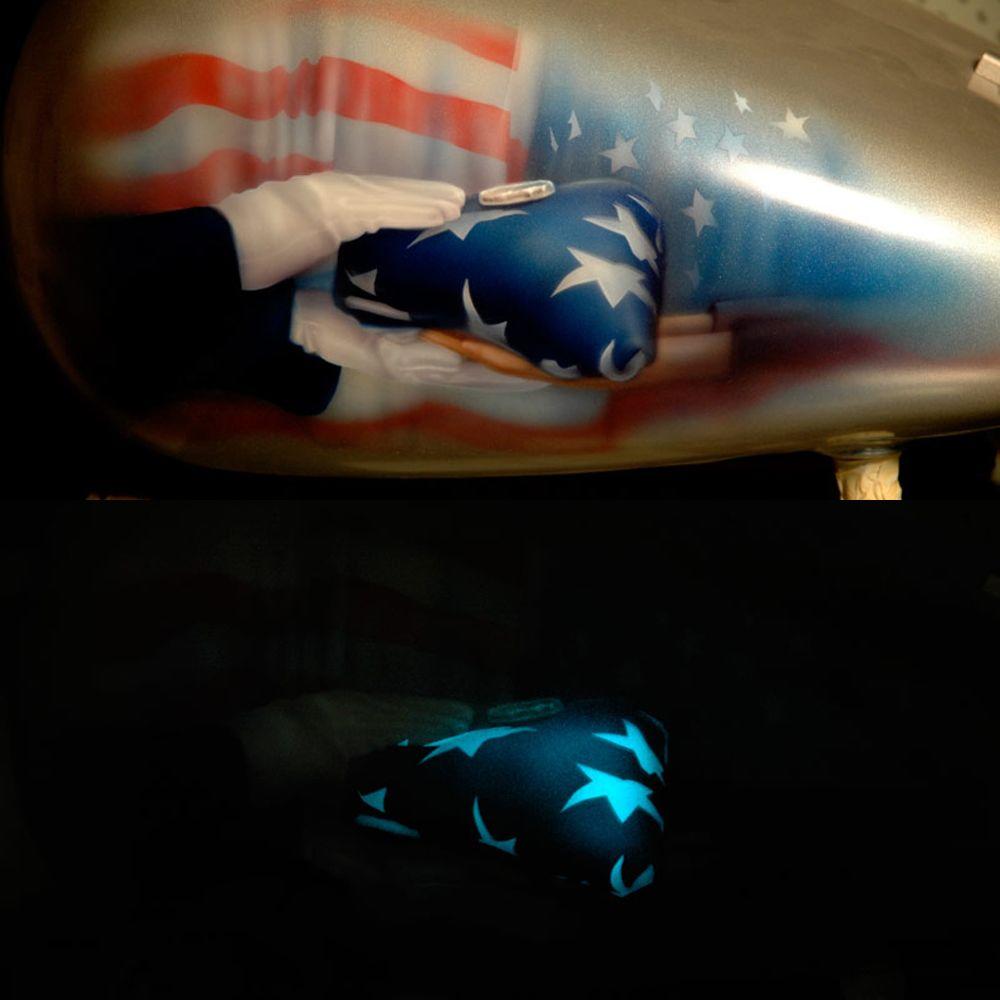

Alsa’s Super Glow powder is a glow in the dark powder additive that is added to any clear carrier, such as a color blender or even your final clear coat, and then applied over an existing WHITE base coat. The duration of glow is directly dependent on the length of the charge. For example, a 2-3hr. charge will equal roughly 2-3hrs. of glow.

- For the first time available to the public, true automotive paint additive & pigment.

- Highly phosphorescent pigment for strong glow, and long glow.

- Ease of use – Simple powder additive

- Dramatic effect

- Great for special effects, and signage